Dener Laser Cutting

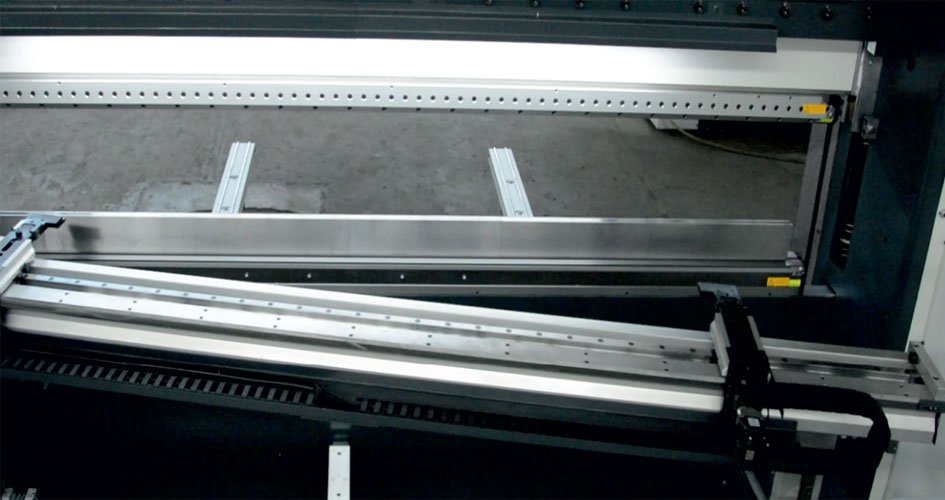

Available lasers: 1KW – 2KW – 3KW – 4KW – 5KW – 6KW – 8KW. The Legend 3015-S is a unique machine with very low energy consumption and very fast cutting capability, along with minimal maintenance costs. The Laser Legend 3015-S machine offers high productivity and superior quality standards. The chip collection covers open and close based on the position of the cutting head. At the same time, this ensures that there are no exhaust gases or smoke in the working environment. The table change system is designed to increase workflow, facilitate material positioning, and reduce part unloading times.

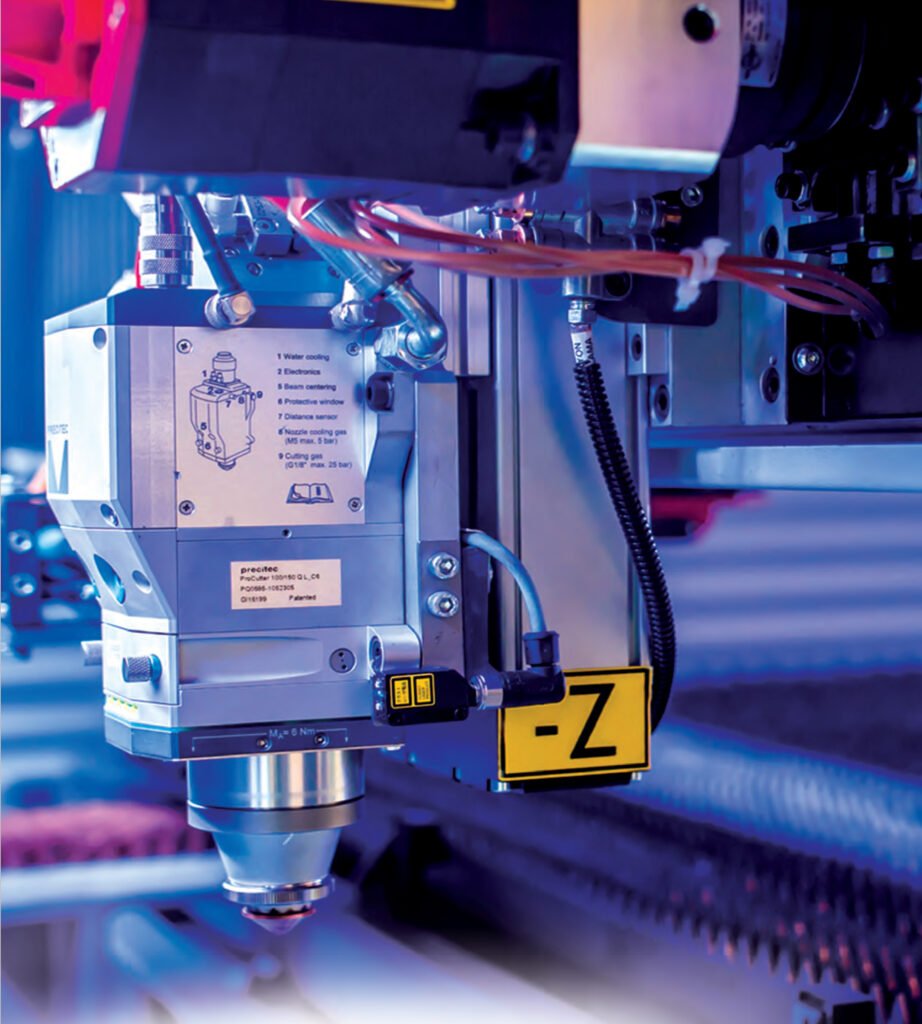

The sheet metal corner and its angles are automatically detected using the 3-point sheet metal detection method. Fiber lasers are inherently designed for maintenance-free production. The importance lies in the diode lifespan, which lasts about 100,000 hours.

The laser solution that counts for you

GFL-3015

GFL-4020

GFL-6020

Laser configuration

Control Unit

Security coverage

Slag cart

Pallet change control unit

Loading and pallet change

Contact us for personalized advice!

Are you looking for a folding solution that combines precision, speed, and reliability? The Dener lasers are designed to exceed your expectations.

Control unit & software

The Fanuc 31i-LB is a top-of-the-line CNC control, optimized for fiber laser cutting machines, distinguished by its high speed and precision. Thanks to sophisticated hardware, with an ultra-fast processor and fiber communication, it ensures high performance and reliability in challenging industrial environments. Its ability to manage up to 24 axes allows for complex automation, while support for different cutting gases (oxygen, nitrogen, compressed air) offers flexibility and economic advantages.

The integration with the Metalix cad/cam software “cncKad” further enhances the system’s capabilities, offering advanced design, automatic positioning, and simulation functions. The combination of hardware and software allows for precise control of the cutting process, optimizing efficiency and productivity.

Fanuc cnc control

The Fanuc 31 i-LB is a CNC control used in our FL fiber laser cutting machines. Fast communication thanks to the higher number of data lines, Fanuc is much faster than competing controls. The number of pieces that can be processed is much higher. The CNC control unit has a maximum of 24 axes that can be integrated into the system to control replacement automation, the tube cutting mechanism, etc. Other optional functions are accessible from a single CNC control.

Set up your Laser

Metalix CAD/CAM Software

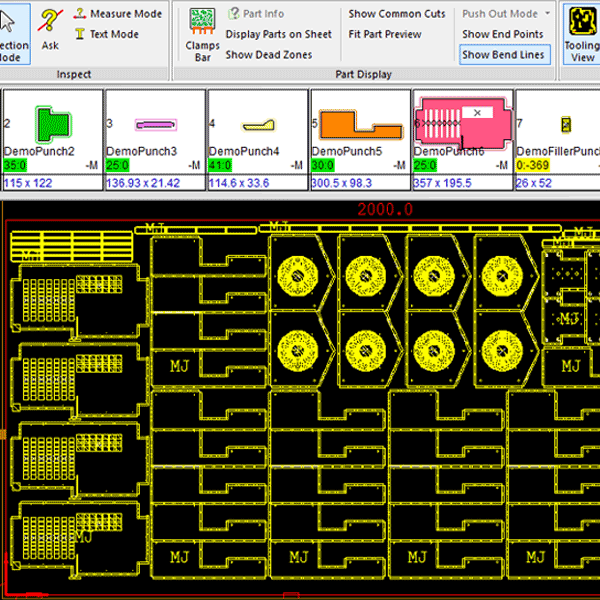

Thanks to the combination of advanced technologies with design functions, automatic and manual processing, automatic positioning, NC code generation, graphic simulation, and machine connection (DNC), Metalix “cncKad” for the sheet metal industry offers precise solutions.

Joint work between Dener and Metalix

The management of laser input and output, rapid drilling (sandblasting), laser movement control, edge binding, marking, film burning, cold cutting, and many other functions have been implemented. With the Autonest Pro function, you get the best possible sheet placement in seconds (optional). Flexible and highly controlled operation is possible with the placement (AutoNest), cutting (Cnckad), and simulation (NC) of parts that can work independently in 3 different sections. In addition to the advanced automatic layout function, you can copy, move, rotate, duplicate, align, etc. You can also effectively use powerful manual layout commands that keep you one step ahead. You can automatically place parts of different sizes and achieve a minimal layout for high placement efficiency. With its powerful drawing infrastructure, you can draw in 2D practically and quickly. Metalix has an effective import function for DXF, SWG, IGES, CADL, GEO, and other standard formats. It also includes support for mm/inch-based files and layers. The CAD link module allows you to transfer parts with a single click to 3D CAD, CNCKAD (optional). It allows you to export parts and layouts or copy layouts to another product tree and always be one step ahead with the quick transition function between layouts. You can view exact cutting times in the placement report, as well as information on the dimensions and weight of the sheet used and the welded parts. With comprehensive documentation, every phase is supported, from settlement to production. It allows you to use all the machine’s features. With Metalix, you can achieve the best performance from the machine, easily turning projects into reality.

Equipment

IPG LASER SOURCE

The power range of the laser source is between 500W – 6 KW. As the power increases, the cutting speed and capacity also increase respectively.

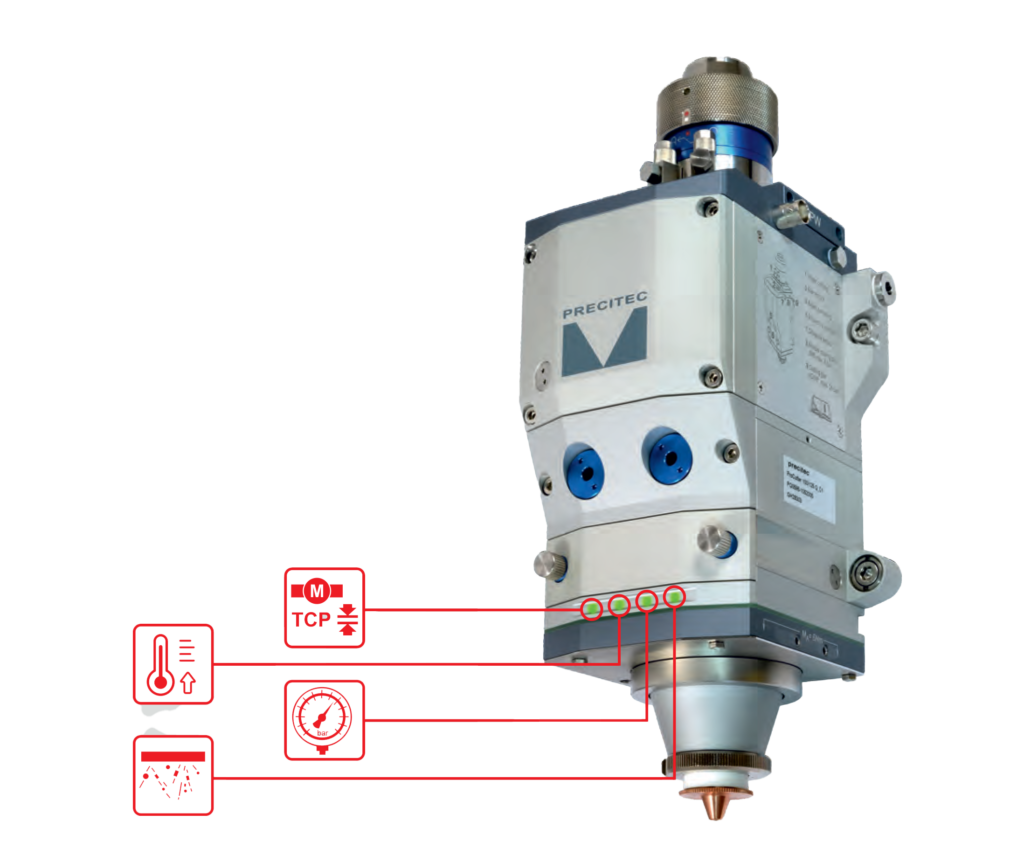

CHILLER IPG

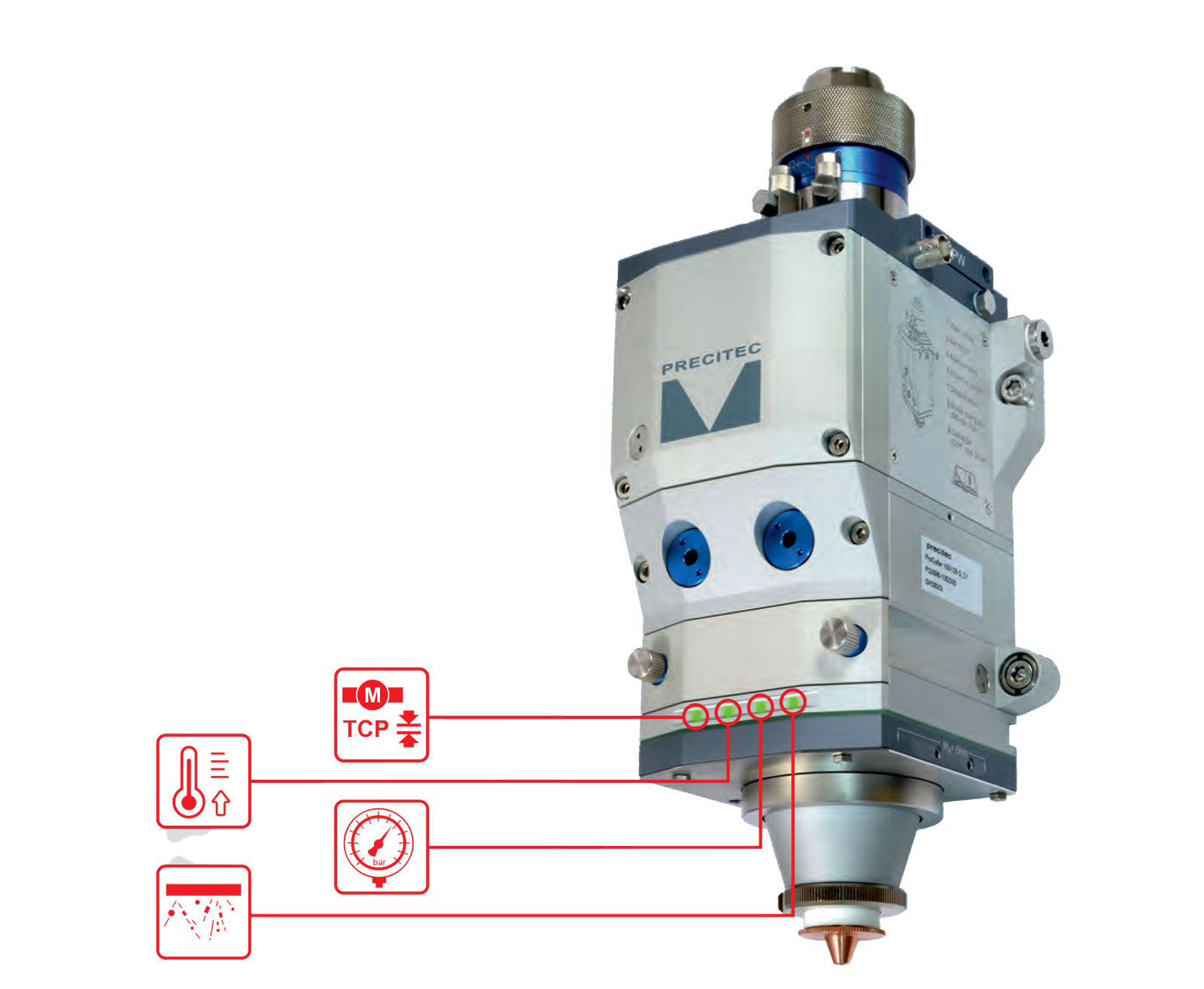

The chiller maintains the optimal temperature of the cutting head necessary to achieve maximum productivity

REFRIGERATED AIR DRYER

The air dryer is standard equipment in the machines. Necessary for a long and efficient operation of the filter and the machine.

FANUC RESONATOR (Advantages)

1- Fanuc Serial Servo Bus (FSSB) allows direct and high-speed control of the oscillator (communication speed 32.25 µs)

2- Edge cutting function, gap control, minute laser output control function

3- Beam reflection protection function

4- High-quality, long-lasting laser module.