Dener hydraulic press

DENER XL press brakes are designed to offer maximum flexibility, reliability and innovation in bending processes. Designed with cutting-edge production technologies, these machines guarantee high quality standards and superior performance. Thanks to a proven design, Dener has enhanced operating speed, stroke, daylight between uprights and bending precision

Equipped with 3D graphic CNC control with ESA S 660 W interface, the PUMA XL allows intuitive and fast programming of operations, even from DXF files. The machine automatically calculates the bending sequence, optimizing time and results. Ideal for those operating in the sheet metal forming sector, DENER XL is the perfect choice to increase productivity and quality in every production cycle.

Dener electric press

DENER CNC electric press brakes represent the evolution of sheet metal bending: machines without hydraulic system, reliable, flexible and highly technological. Designed for a more sustainable future, they combine productivity, precision and low energy consumption, eliminating the use of hydraulic oil and drastically reducing maintenance.

Equipped with an advanced CNC control, quick and precise clamping systems for punches and dies and a multi-axis back gauge, these presses allow sheet metal bending with very high efficiency and at minimum operating cost. The ideal choice for those seeking a green solution without sacrificing performance.

Configure your Dener Press

Dener ballscrew press brakes

High Efficiency, Zero Oil, Maximum Precision

DENER Ball Screw press brakes are machines without hydraulic system, designed to offer flexibility, reliability and advanced performance. They represent a new generation of green, eco-sustainable machines that combine productivity, precision and low energy consumption. No use of hydraulic oil, less maintenance and maximum respect for the environment.

Equipped with advanced CNC control, quick and precise clamping of punches and dies, and a multi-axis back gauge system, these presses allow operators to produce sheet metal parts with extreme ease and very low operating costs. The intelligent choice for a sustainable and high-performance future.

Dener Laser

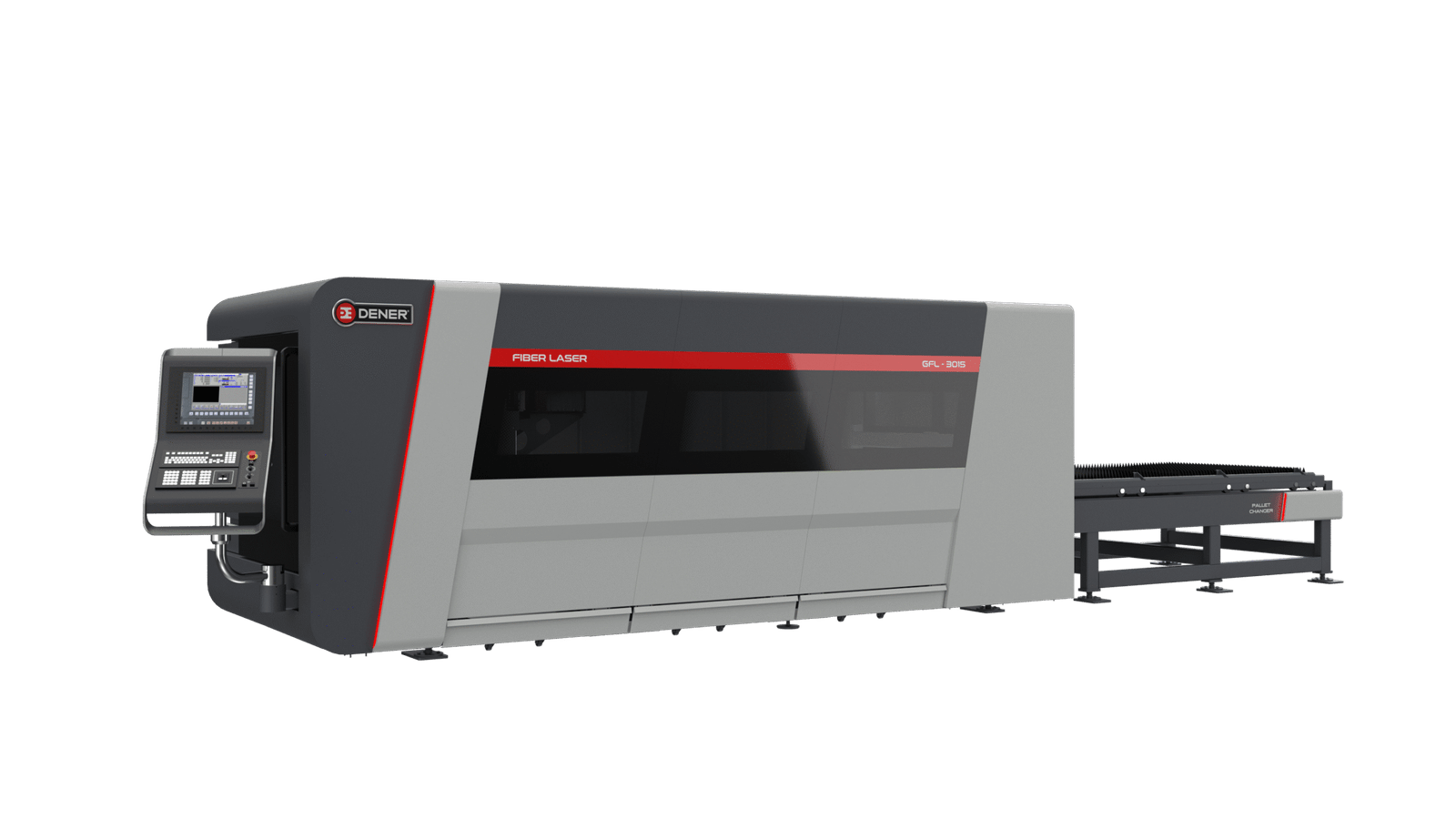

DENER GFL: High-Performance Fiber Laser Technology for Precise and Fast Cuts

The DENER GFL Gantry Laser Cutting Machine represents excellence in fiber laser cutting, combining high cutting speed (up to 120 m/min), millimetric precision (positioning accuracy of 0.05 mm) and a compact and modern design. The welded and machined frame with 5-axis technology guarantees resistance to high accelerations and long life, while the automatic dual pallet system allows continuous and uninterrupted production.

Equipped with FSCUT4000E / FSCUT8000C CNC controller, intuitive interface and intelligent nesting and edge detection functions, the machine offers efficient and simple management. Laser power options from 3kW up to 20kW and compatibility with a wide range of materials (stainless steel, carbon steel, aluminum, etc.) make it perfect for every production requirement.

Dener Shear

Precise, Robust and Automated Cutting for Every Need

DENER CNC shears offer robust mechanics, high-precision ball screw back gauge and an intuitive CNC control, ideal for achieving high performance in sheet metal cutting. Made of welded steel and designed to last over time, they guarantee structural rigidity and resistance to torsion and deformation, thus ensuring superior cutting quality.

DENER shears support cutting thicknesses from 6 mm up to 20 mm and lengths from 3 to 6 meters as standard, with possibility of customization on request. The CNC controller simplifies operations: the operator enters the thickness and material type, and the system automatically adjusts the cutting angle and blade clearance, optimizing the process quickly and efficiently.

FAQ – Frequently Asked Questions