Ball Screw Press Brakes

Dener Ball Screw Press Brakes are hydraulic-free, flexible, reliable, and advanced bending machines. A new generation machine concept that combines productivity, accuracy, flexibility, and reliability in an eco-friendly and sustainable way. The new concept offers low energy consumption, less maintenance, and operates without hydraulic oil.

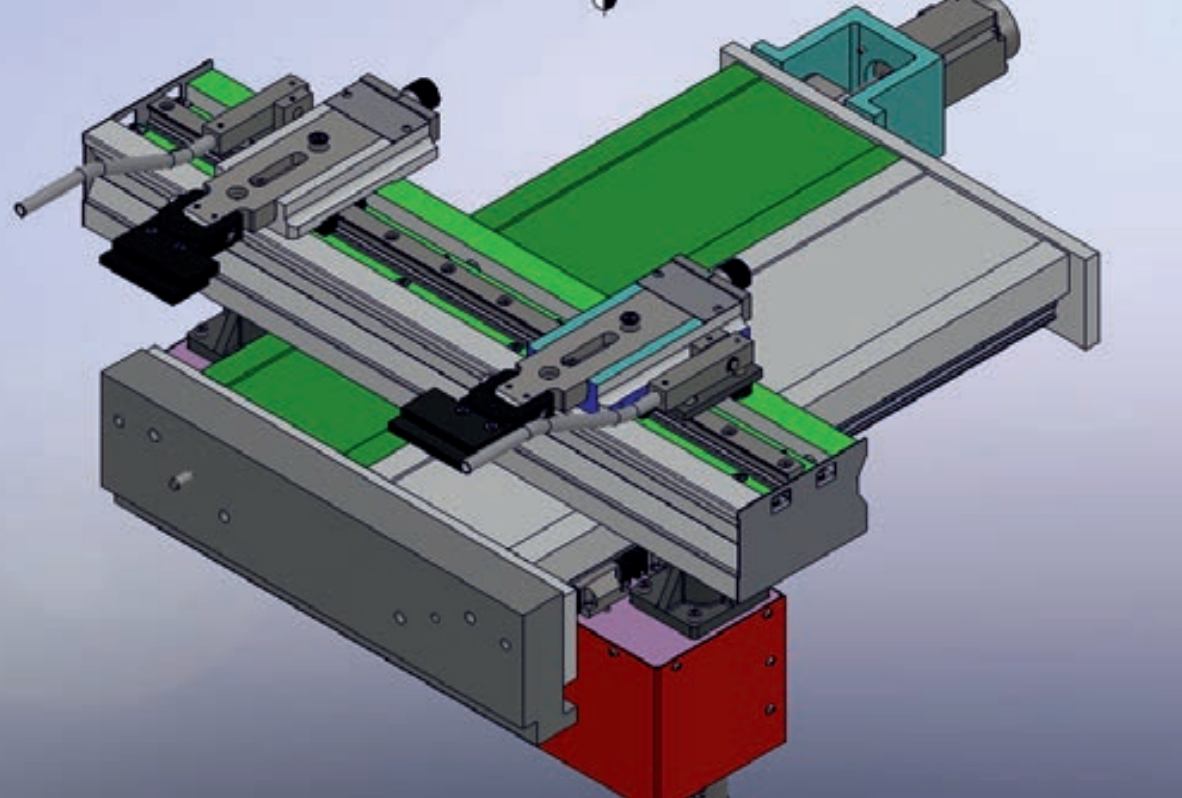

The Ball Screw Press Brake is equipped with an advanced CNC controller, fast and accurate punch and die clamping system, and a multi-axis back gauge system. Operators can easily make sheet metal parts at very low costs.

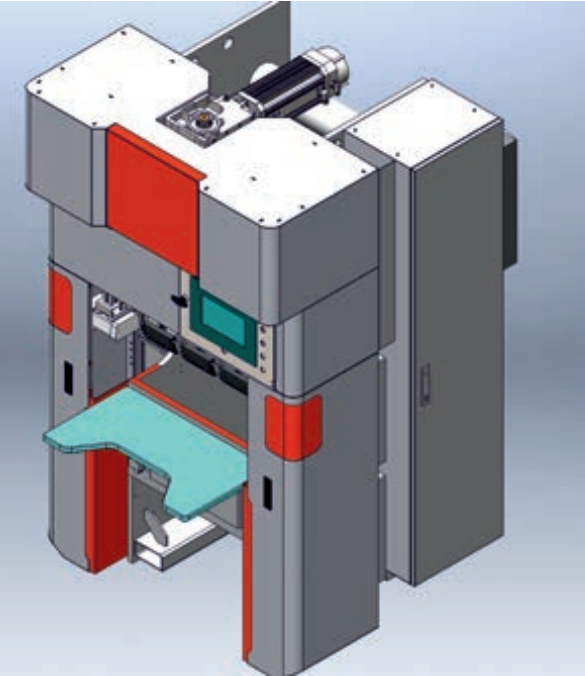

Press Configuration

Laser Front Protection System

Standard Punch Attachment (European)

LED Lights

Front Rear

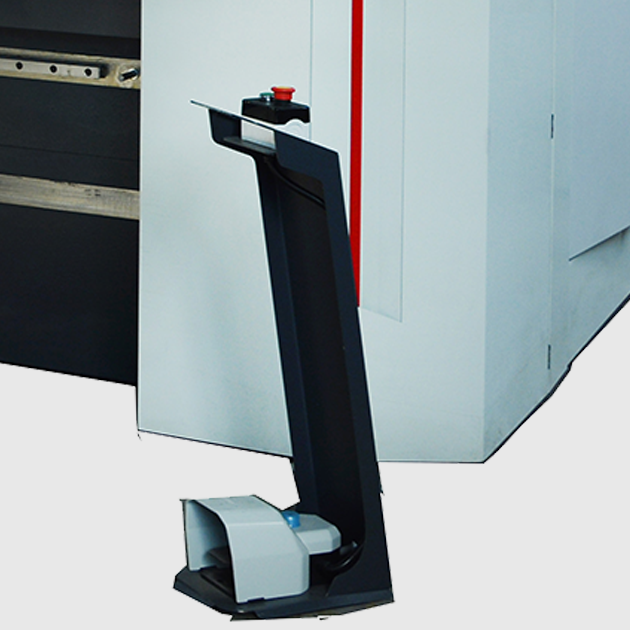

Pedal with Emergency Button

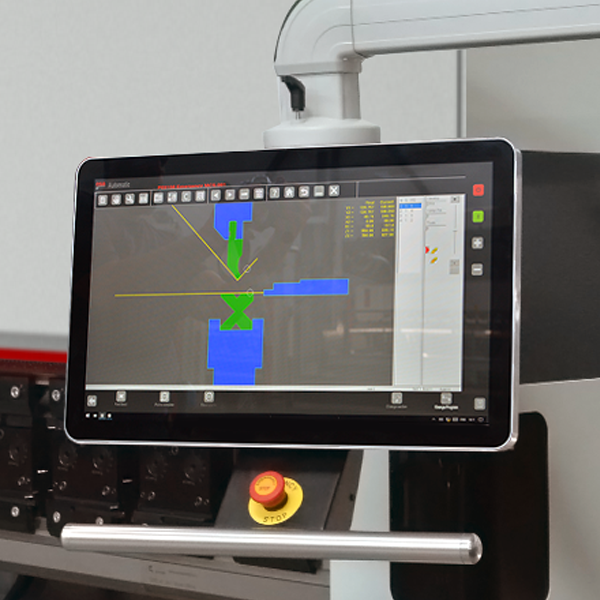

Control

Unit

Customization of Ball Screw Press Brakes

Are you looking for a bending solution that combines precision, speed, and reliability? Ball Screw press brakes are designed to exceed your expectations.

Efficiency and Precision of Ball Screw Press Brakes

Dener’s Ball Screw Press Brakes, often part of their Servobrake DOS line, represent Dener’s commitment to compact, high-efficiency bending solutions. These machines use a ball screw drive system instead of traditional hydraulics, offering benefits such as reduced energy consumption (up to 50% less than hydraulic models), lower maintenance costs due to the elimination of hydraulic oil, and faster bending speeds (up to 35% faster). They are designed for high precision and are considered more eco-friendly with lower operating noise. Equipped with advanced CNC control units like the ESA 875 W, they offer user-friendly interfaces with 2D and 3D graphical programming, automatic bending sequence calculation, and tool selection, often featuring large touchscreens for intuitive operation. The optional ergonomic work table further enhances the user experience, making the bending process more comfortable and efficient.

Work Table

The folding, adjustable, and ergonomic work table

makes bending processes easier and more comfortable

Clamping and Tooling

European model punch and die clamping system.

Wila mechanical and hydraulic clamping system (Optional)

Equipment

Body Structure

Solid monoblock body with C-frame allowing high precision in bending.

Safety

System

Fiessler laser is delivered with Fiessler safety PL

Back Gauge

the 2-axis back gauge processes complex parts with ease.

(5-axis optional – Z1, Z2, and X-Prime with control unit

ESA660)

Additional Advantages

Cooled electrical cabinet.

Easier box bending with greater height opening.

Speed in transport and installation.