Dener Shear

SERIES AS

DENER CNC GUILLOTINE SHEAR

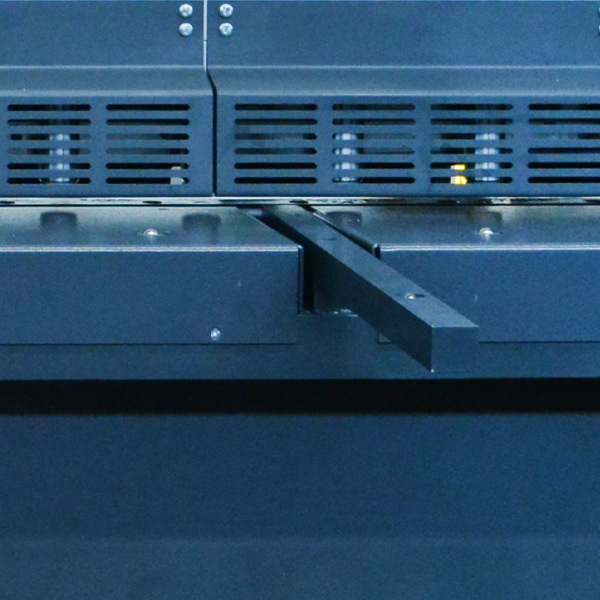

The Dener Guillotine Shear provides rock-solid mechanics, hydraulic system, precise ball screw back gauge, user-friendly CNC controller, and high-productivity shears. Dener shears have a sheet metal cutting capacity from 6mm up to 220mm in thickness, cutting length from 3m up to 6m as standard, and machines with greater capacity are available upon special request.

The Dener Shear has a robust welded steel structure suitable for long operating times. The frame design, cutting beam, and back gauge ensure maximum rigidity and resistance to twisting and deformation. Thanks to the sturdy design, customers can achieve the highest cutting quality.

With the easy-to-use CNC controller, the operator enters the thickness and type of material, and the controller automatically adjusts the cutting angle and blade distance.

Configuration of the Dener Shear

Control Unit with

7T TFT LCD Display

Remote control pedal

with emergency

stop button

Front protective panel

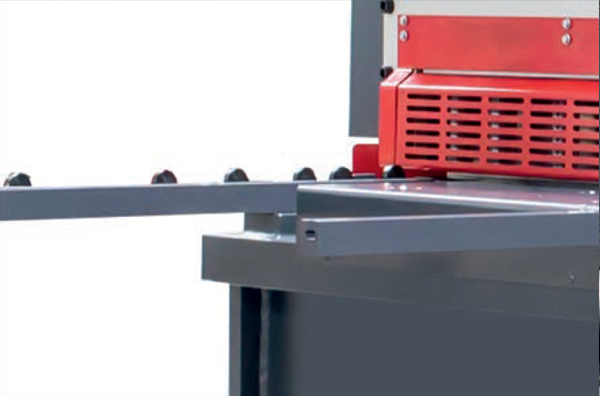

Front support arms with T-slot

Sliding control in foil

Contact us for personalized advice!

Are you looking for a folding solution that combines precision, speed, and reliability? Dener Shears are designed to exceed your expectations.

Other configurations

Front support arm

Replacement blades

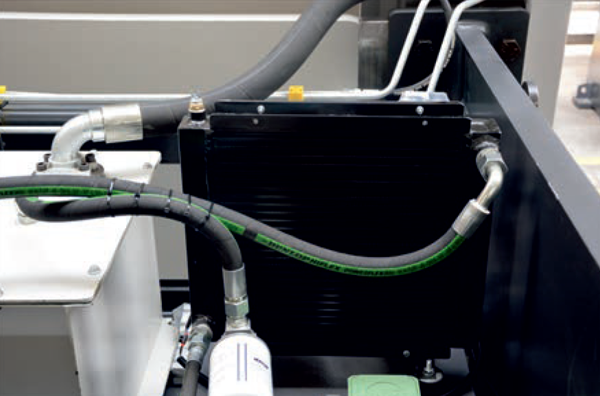

Hydraulic oil cooling system

Pneumatic laminate support system

Laser cutting line

Robustness and Ease of Use for Sheet Metal Cutting with the Dener Shear

The Dener shear combines solid mechanics, a precise control system with ball screw, and an intuitive CNC interface, offering high performance and top-quality cuts. Designed to ensure high productivity, Dener shears allow cutting of sheets with thicknesses from 6 mm to 20 mm and lengths between 3 and 6 meters. Customized solutions are also available upon request.

Made of high-strength welded steel, these machines are built to last over time. The design of the frame, cutting beam, and back gauge is engineered to offer maximum structural rigidity, preventing twisting and deformation even under stress. Thanks to this robustness, a precise and consistent cut is achieved, even in the most demanding tasks.

The CNC control facilitates the operator’s work: simply enter the thickness and type of material to allow the machine to automatically adjust the cutting angle and the distance between the blades.

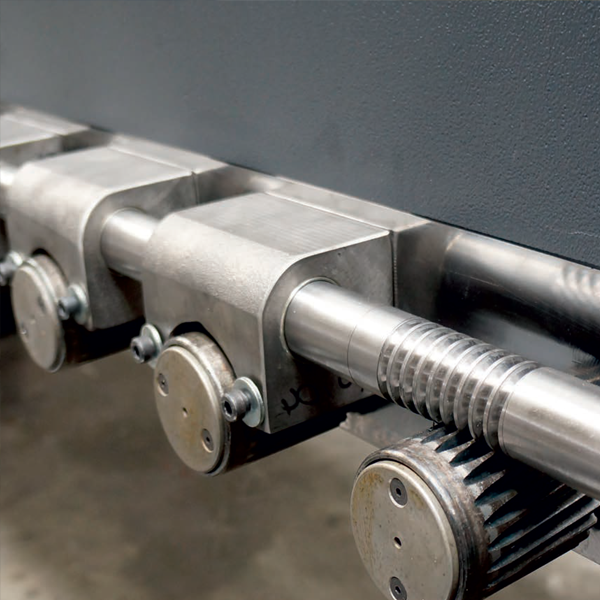

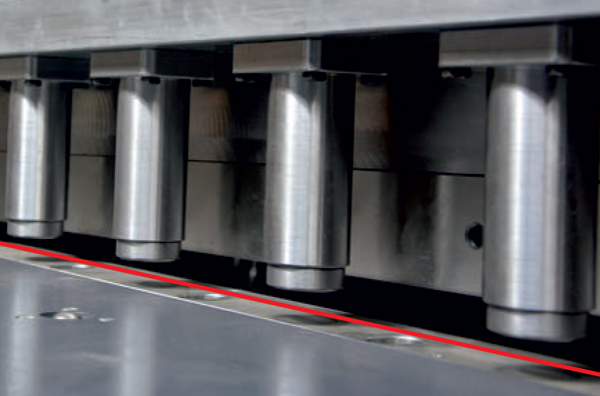

Blade bearing system

The Blade Pads system ensures linearity and precision in all conditions, thus achieving the best cutting quality.