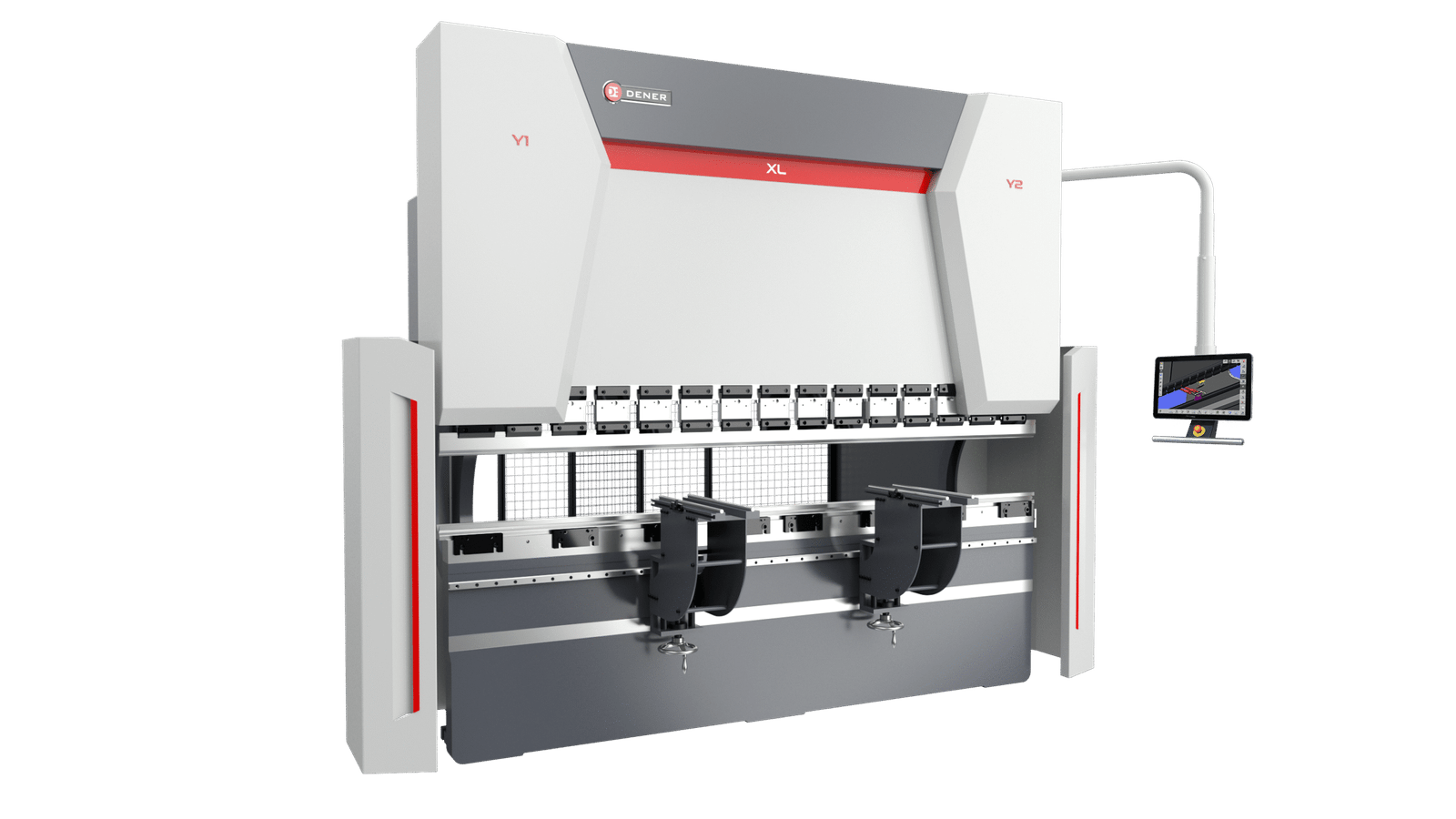

DENER XL CNC Press Brakes

were born with the aim of being flexible, reliable, and advanced; Dener uses the most rigorous manufacturing technologies to produce machines of the highest quality. Based on a proven design, Dener has increased the working speed, stroke, daylight, and pressing capacities of the XL machines.

DENER XL is a synchronized hydraulic press brake with a 3D Graphical CNC controller offering simple operation, 3D or numerical programming, and easy bending setup for automatic bending sequence calculation. The 3D and DXF programming function with ESA S 675 W offers end-users the possibility to program these functions, making Dener XL CNC hydraulic press brakes very popular in the sheet metal industries.

Hydraulic press configuration

Other hydraulic press configurations

Front and rear lights

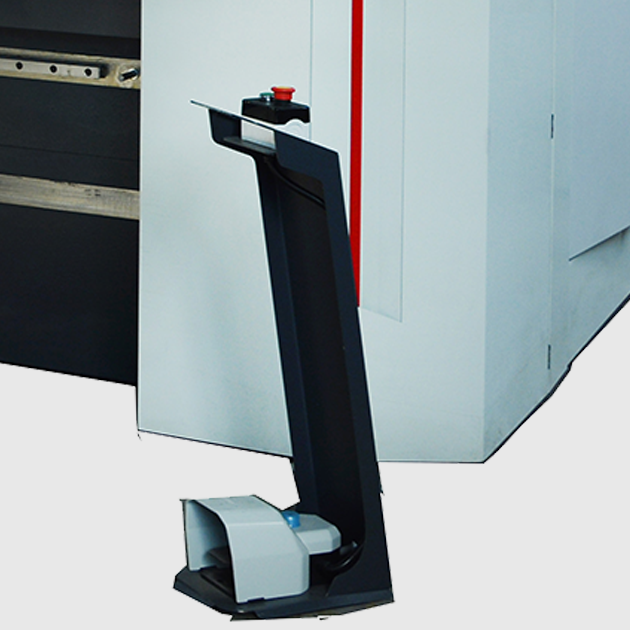

Pedal with emergency button

Laser DSP system

Increased throat

Bending angle control system

Contact us for a personalized consultation!

Are you looking for a bending solution that combines precision, speed, and reliability? DENER XL CNC press brakes are designed to exceed your expectations.

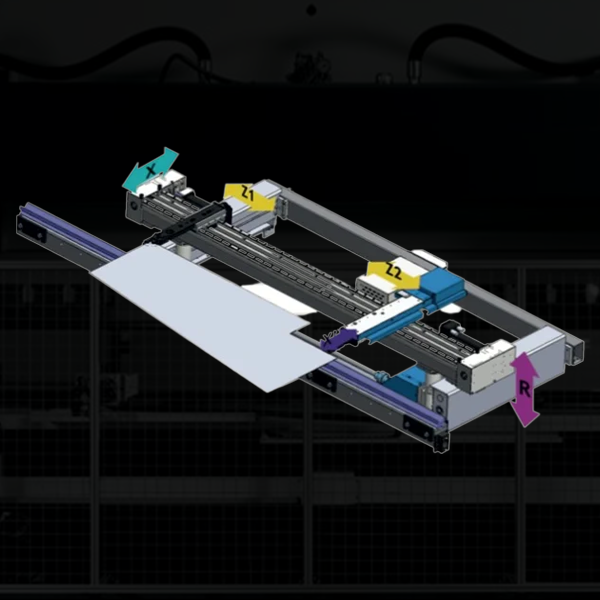

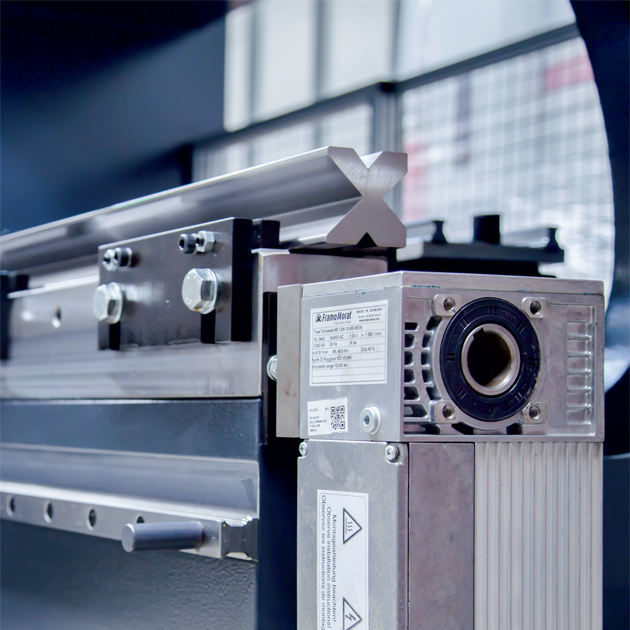

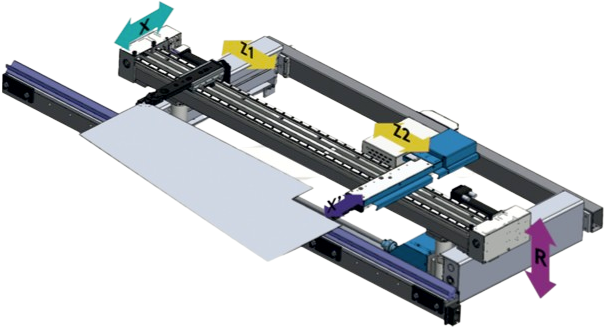

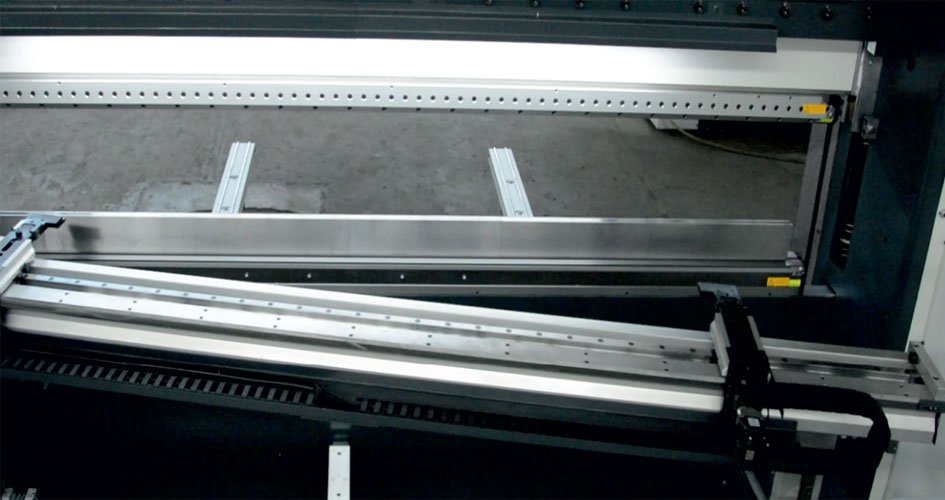

Back gauge of the hydraulic press

The back gauge is a main concept for press operators. Whether a complete multi-station bending or single station is required, the XL offers solutions with 6 different back gauge options. Based on the geometry of the parts and their complexity, all back gauge models are specially designed to achieve high precision and high speed.

Standard back gauge

system

Optional back gauge

system

Optional back gauge equipment

X, R assi

X, R, Z1, Z2 assi

X, R, Z1, Z2, X Prime assi

ATF – X1, X2, R1, R2, Z1, Z2 assi

X1, X2, R, Z1, Z2

Hydraulic press technical specifications

| XL | 1560 | 2060 | 2660 | 26100 | 30100 | 30135 | 30175 | 30220 | 30320 | 36175 | 36220 | 36320 | 40175 | 40220 | 40320 | 40400 | 40600 | 60220 | 60320 | 60400 | 60600 |

| Bending length (mm)(A) | 1550 | 2050 | 2650 | 2650 | 3020 | 3020 | 3020 | 3020 | 3020 | 3650 | 3650 | 3650 | 4050 | 4050 | 4050 | 4050 | 4050 | 6050 | 6050 | 6050 | 6050 |

| Bending capacity (ton) | 60 | 60 | 60 | 100 | 100 | 135 | 175 | 220 | 320 | 175 | 220 | 320 | 175 | 220 | 320 | 400 | 600 | 220 | 320 | 400 | 600 |

| Approach speed (mm/s) | 180 | 180 | 180 | 160 | 160 | 160 | 150 | 140 | 140 | 150 | 140 | 140 | 150 | 140 | 140 | 80 | 60 | 100 | 80 | 60 | 60 |

| Bending speed (mm/s) | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 8 | 8 |

| Return speed (mm/s) | 160 | 160 | 160 | 150 | 150 | 140 | 130 | 130 | 120 | 130 | 130 | 120 | 130 | 130 | 120 | 80 | 60 | 100 | 80 | 60 | 60 |

| Stroke (C) | 220 | 220 | 220 | 300 | 300 | 320 | 350 | 350 | 400 | 350 | 350 | 400 | 350 | 350 | 400 | 400 | 455 | 350 | 350 | 400 | 455 |

| Opening (D) | 410 | 410 | 410 | 530 | 530 | 550 | 600 | 600 | 650 | 600 | 600 | 650 | 600 | 600 | 650 | 650 | 650 | 600 | 650 | 650 | 680 |

| Frame throat depth (E) | 400 | 400 | 400 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 450 | 600 | 600 | 450 | 450 | 600 | 600 |

| Frame gap (B) | 1250 | 1650 | 2150 | 2150 | 2555 | 2555 | 2555 | 2555 | 2555 | 3100 | 3100 | 3100 | 3550 | 3550 | 3550 | 3550 | 3550 | 5100 | 5100 | 5100 | 5100 |

| Length (L) | 2445 | 2845 | 3345 | 3320 | 3725 | 3745 | 3745 | 3745 | 3785 | 4290 | 4290 | 4330 | 4740 | 4740 | 4780 | 5000 | 5000 | 6775 | 6815 | 6855 | 7100 |

| Max width (W) | 2200 | 2200 | 1930 | 2260 | 2260 | 2250 | 2290 | 2290 | 2290 | 2290 | 2290 | 2290 | 2290 | 2290 | 2290 | 2770 | 2500 | 2650 | 2500 | 2500 | 2660 |

| Width without front supports (Y) | 1330 | 1335 | 1330 | 1695 | 1670 | 1710 | 1710 | 1710 | 1740 | 1710 | 1710 | 1740 | 1710 | 1710 | 1725 | 2310 | 3130 | 1760 | 1760 | 2270 | 3190 |

| Height (H) | 2390 | 2390 | 2390 | 2400 | 2770 | 2825 | 3025 | 3050 | 3100 | 3025 | 3050 | 3100 | 3025 | 3050 | 3100 | 3555 | 3755 | 3000 | 3100 | 3605 | 3755 |

| Working table height (F) | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 920 | 920 | 920 | 920 | 920 | 920 | 920 | 920 | 1095 | 920 | 920 | 1095 | 1000 | 1000 |

| Pit depth | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 850 | 0 | 0 | 0 | 1030 |

| Main motor (KW) | 7.5 | 7.5 | 7.5 | 11 | 11 | 15 | 22 | 22 | 30 | 22 | 22 | 30 | 22 | 22 | 30 | 45 | 45 | 22 | 30 | 45 | 45 |

| Oil (liters) | 100 | 100 | 100 | 190 | 190 | 190 | 300 | 300 | 400 | 300 | 300 | 400 | 300 | 300 | 400 | 400 | 600 | 300 | 400 | 400 | 600 |

| Approximate weight | 4250 | 4800 | 5500 | 7900 | 8550 | 9500 | 11500 | 11700 | 14450 | 12200 | 12350 | 15450 | 13100 | 13200 | 17650 | 24500 | 40500 | 18000 | 22850 | 31200 | 50000 |

Talk to an expert and customize your hydraulic press!

Every company has different needs, which is why customizing your press brake is crucial. Whether it involves specific dimensions, advanced features, or tailored functionality, our team is ready to work with you to create a solution that optimizes your production. Contact us to discover how we can adapt the press brake to your requirements, ensuring efficiency, precision, and performance.