Flatbed Laser Plus

Power up to 50 kW

Flatbed Laser Plus by Cutlite Penta represents the pinnacle of technology for metal laser cutting. Designed to offer maximum production efficiency, this machine uses a fiber laser source up to 50 kW, ideal for complex processing on carbon steel, stainless steel, and other metals.

Thanks to high-performance linear motors, the system ensures rapid and precise movements, maintaining very high quality standards even in the most intense cycles. The entire structure is built in electro-welded steel, designed to guarantee stability, rigidity, and reliability over time.

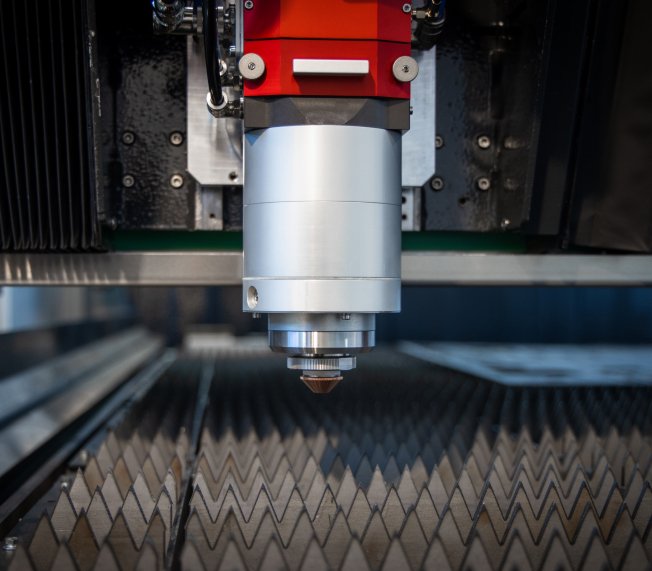

EVO 3 Head

Equipped with the EVO 3 cutting head developed internally by Cutlite Penta, the machine guarantees advanced performance thanks to:

- Intelligent autofocus

- Thermal and contact sensors

- Safe use up to 50 kW and 25 bar pressure

It is compatible with various focal configurations, to adapt to any type of processing.

Bevel Head

For processing complex thicknesses or angled profiles, the Bevel head allows rotations up to ±45°, maintaining the compact dimensions of the standard machine. No structural changes, no loss of functionality: just pure versatility.

Laser Sources

The integrated fiber laser sources guarantee:

- High energy efficiency

- Excellent laser beam quality

- Low operating costs and minimal maintenance

Everything is contained in a sealed and air-conditioned cabinet (NEMA 12 standard), perfect even for harsh industrial environments.

Customize your Flatbed Laser Plus!

Are you looking for a bending solution that combines precision, speed, and reliability?

Cutlite Penta’s Flatbed Laser Plus are designed to exceed your expectations.

Mechanical Structure of Flatbed Laser Plus

Hardware Accessories for Flatbed Laser Plus

Automatic nozzle changer

Allows detection of the weld seam position (both external and internal) before the bar is loaded into the machine, in time completely masked by the processing of the previous bar

Camera

Allows detection of the weld seam position (both external and internal) before the bar is loaded into the machine, in time completely masked by the processing of the previous bar

Two-level table changer

Allows detection of the weld seam position (both external and internal) before the bar is loaded into the machine, in time completely masked by the processing of the previous bar

Pallet lift changer

This option allows optimization of processing times, reducing sheet metal loading and unloading times.

Automation

This option allows optimization of processing times, reducing sheet metal loading and unloading times.

Contact us for a personalized consultation!

Contact us for tailored advice: we are ready to configure the perfect PLUS laser machine for your company.