Flatbed Laser LME

Power up to 20 kW

Flatbed Laser LME – High Precision and Reliability for Metal Cutting

The Flatbed Laser LME by Cutlite Penta is the ideal choice for those seeking a high-precision laser cutting system, designed to ensure high performance and low operating costs. With a cutting power of up to 20 kW, the Flatbed Laser LME is capable of precise cuts on carbon steel, stainless steel, and other metals, ensuring exceptional cutting quality even on complex geometries.

This innovative system stands out for the use of advanced linear motors that, together with the fiber laser source, allow for unparalleled cutting accuracy. The optimized laser path configuration, combined with a highly performing EVO 3 cutting head, makes the LME Flat Laser one of the most efficient tools on the market.

Advanced Technology for Perfect Cuts

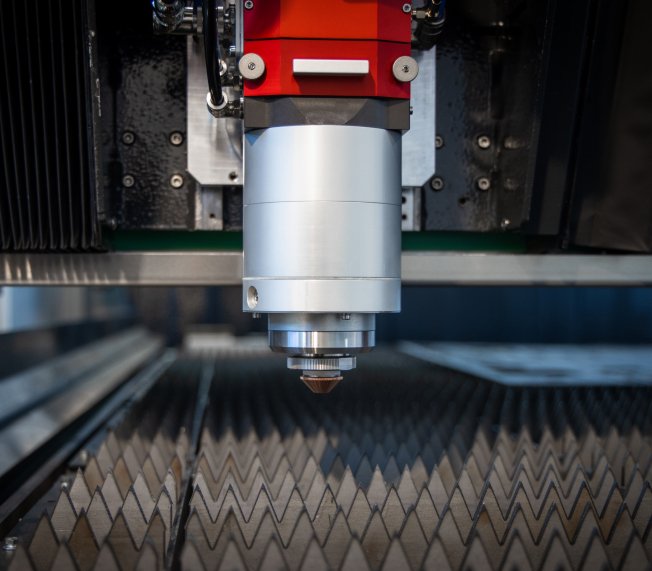

The Flatbed Laser LME is equipped with an EVO 3 cutting head, designed and manufactured by Cutlite Penta to maximize precision during cutting. Equipped with a capacitive sensor and advanced temperature and contact sensors, the EVO 3 cutting head ensures perfect control and quick adaptation to variations in materials and thicknesses, improving the overall quality of the cut.

The integrated autofocus system automatically adjusts the distance of the cutting head, optimizing the setup and ensuring consistent and repeatable cutting quality.

Cutting Head EVO 3

The EVO 3 cutting head of the Flatbed Laser LME is designed to ensure the highest level of precision and reliability. Equipped with a capacitive sensor, this advanced head allows for precise control during cutting, maintaining consistent quality across various types of materials. The integrated autofocus system automatically adapts to different thicknesses and types of metal, improving efficiency and reducing setup times.

Designed internally by the research and development department of Cutlite Penta, the EVO 3 head is made with high-precision mechanics to ensure superior performance over time. It is equipped with advanced contact and temperature sensors, which optimize the cutting process and enhance its reliability.

Laser sources

The fiber laser sources of the Flatbed Laser LME offer extraordinary versatility, allowing the cutting of a wide range of metals, including carbon steel and stainless steel. This system is designed as a single module, which can be combined with a variety of fiber optic diameters, to suit the needs of each processing operation.

The fiber laser sources are renowned for their high energy efficiency, excellent beam quality, and low electrical consumption. These characteristics allow for a significant reduction in operating costs, increasing the productivity and lifespan of the machine. Additionally, the laser source is housed in a NEMA 12 cabinet, which protects it from dust and contaminants, allowing it to operate even in harsh industrial environments. Thanks to this advanced protection, maintenance costs are minimized.

Contact us to Discover the LME Flat Laser

If you are looking for a laser cutting system that combines precision, efficiency, and reliability, the LME Flat Laser is the ideal solution for you. Cutlite Penta offers personalized consultations to help you choose the system best suited to your production needs. Discover how our LME Flat Laser can improve your productivity and reduce operating costs.

Mechanical structure

The mechanical structure is built with a welded steel base, ensuring strength and rigidity even in the most challenging operating conditions. The high-precision machining allows for the installation of linear guides and linear motors, ensuring excellent dynamic performance.

The Gantry beam is designed to be lightweight and rigid, compensating for thermal expansions without compromising the system’s alignment and precision. This innovative design allows the LME Flat Laser to deliver superior performance, without deformations, even during operation at high temperatures.

Hardware Accessories for Flat Laser LME

Automatic nozzle change

The automatic nozzle change is an option that allows the machine to automatically replace the cutting head nozzle without the operator’s assistance.

Camera

It is a position camera that allows remote monitoring and viewing of the machine’s work.

Change bank on two levels

The two-level table change allows the replacement of the workbench in about 15 seconds, almost completely masking the loading and unloading times.

Manual extraction bench

Manual extraction bench for loading and unloading materials to be processed.

Customize your Flatbed Laser!

Are you looking for a folding solution that combines precision, speed, and reliability?

The Flatbed Lasers LME by Cutlite Penta are designed to exceed your expectations.