The servo electric press brake is a non-hydraulic, flexible, reliable and advanced bending machine.

This new generation machine concept combines eco-friendly machines with productivity, accuracy, flexibility and reliability. The new concept offers low consumption, less maintenance and no hydraulic oil for operations

The Servo electric press brake comes with advanced CNC control, fast punch care and die clamping, and a multi-axis back gauge system.

Operators can easily make sheet metal parts at low costs.

Dener uses the most rigorous processing technologies during production to produce high quality machines

Press Configuration

Other Configurations

Back

Gauge

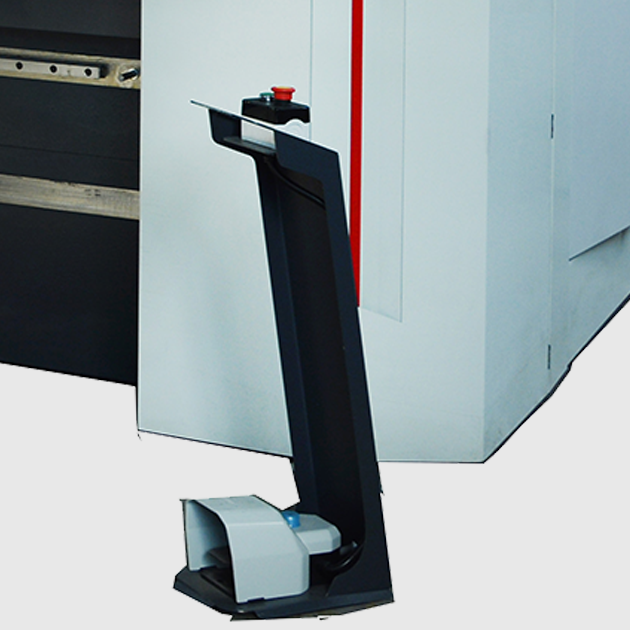

Foot pedal with emergency button

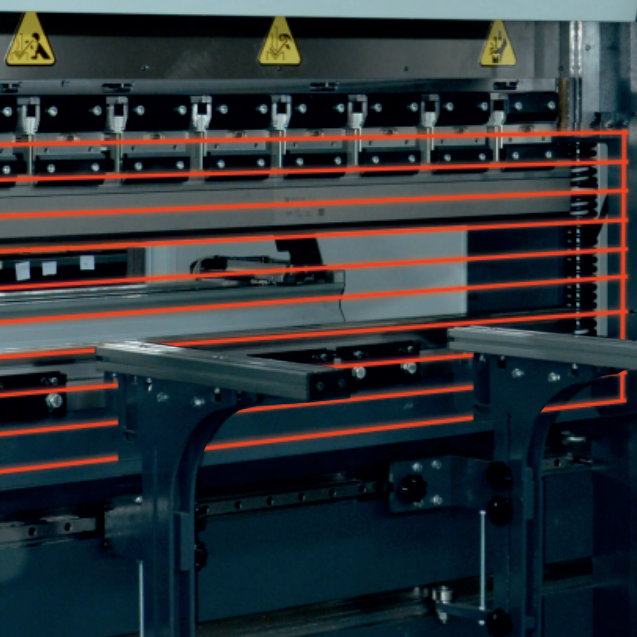

Front laser protection system

Photoelectric

Barriers with CE

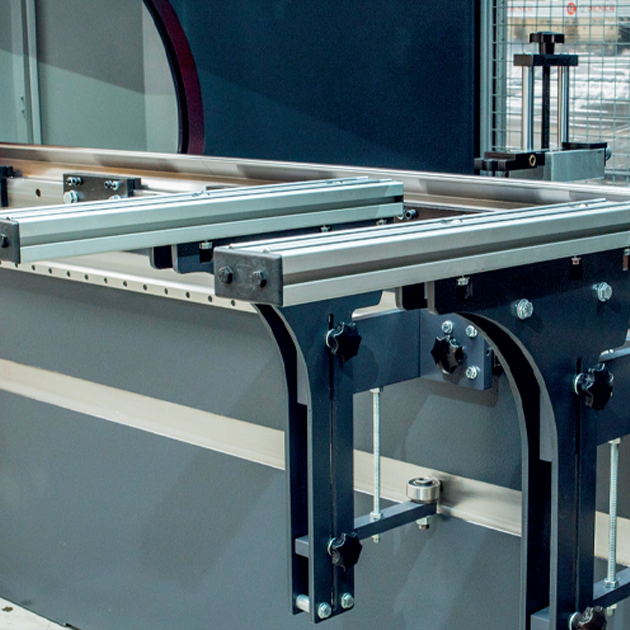

Compensation

Table

Contact us for a personalized consultation!

Are you looking for a bending solution that combines precision, speed and reliability? Electric press brakes are designed to exceed your expectations

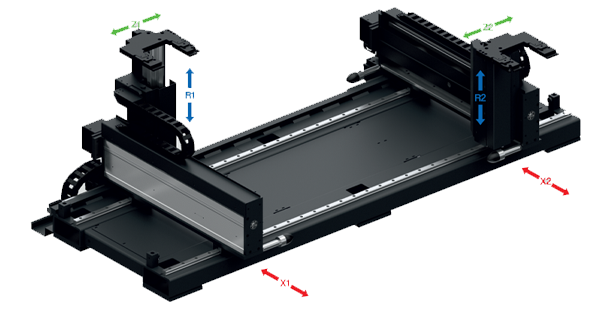

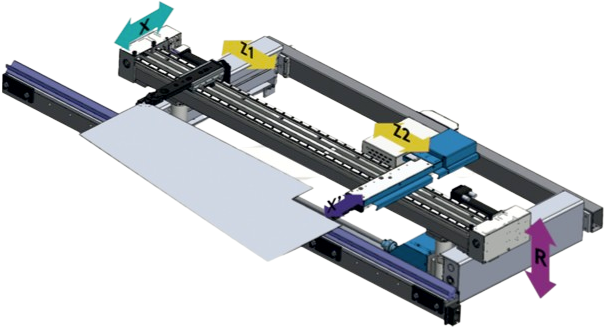

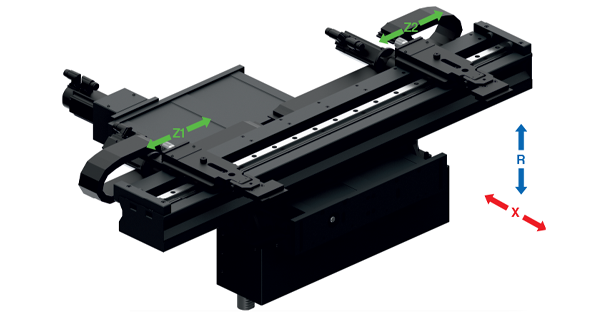

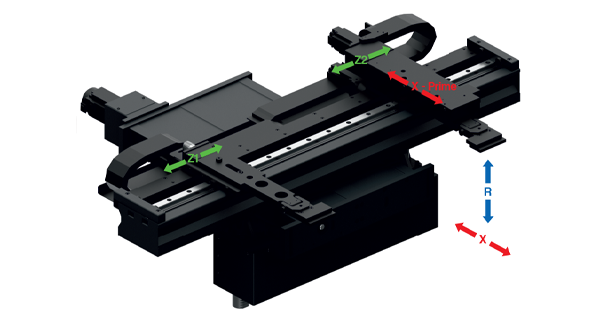

Back Gauge

Measurement is one of the main concerns for press brake operators. Whether you require multi-station bending of complex parts, single bending or the production of conical bends, the SERVO electric press brake offers solutions with six different back gauge options. Depending on the geometry of the parts and their complexity, all back gauge models are specially designed and manufactured to achieve high precision and high speeds.

Standard

Back Gauge System

Optional

Back Gauge System

Optional Back Gauge Equipment

X, R, Z1, Z2

X, R, Z1, Z2 + X Prime

X1, X2, R, Z1, Z2