Tube Laser Cutting

Tube Laser Cutting: Three-Dimensional Precision for Your Structures

The tube laser cutting represents cutting-edge technology for processing metal tubes and profiles, offering extreme precision and flexibility. Thanks to a laser beam controlled by CNC systems, it is possible to perform complex cuts, holes, bevels, and three-dimensional machining on a wide range of tubular materials.

Advantages of Tube Laser Processing:

We perform intricate machining on curved and angled surfaces with precise and repeatable results. We can process tubes in steel, aluminum, stainless steel, and other metals, adapting to various application needs. The fast and automated process optimizes processing times and reduces costs. The localized heat of the laser limits tube deformation, preserving its mechanical characteristics. The cut edges are clean and burr-free, often eliminating further machining.

Applications of Tube Laser Cutting:

This technology is essential in the automotive industry for the production of frames and exhaust systems. In the construction sector, it enables the creation of complex metal structures and designer railings. The furniture industry exploits precision to create unique furniture and accessories. It is also used in the production of industrial plants and aerospace components.

Why Choose Tube Laser Cutting?

If you are looking for a precise, efficient, and versatile processing method for your tubular structures, tube laser cutting is the ideal solution. Whether you need to produce complex structural components or unique design elements, you will achieve high-quality results quickly.

Showing all 3 resultsSorted by latest

-

View ProductWorking area:12 mm - 305 mm RoundPower:2 Kw - 6 KwMaximum thickness:25 mm on FeAutomation:Automatic tube loadingYear:2025

-

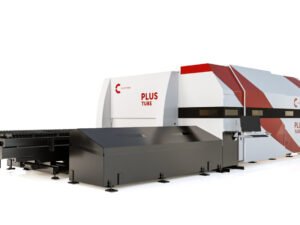

View ProductWorking area:3000x1500 mmPower:2 Kw - 15 KwMaximum thickness:12 - 40 mm on FeAutomation:Sheet loading and unloadingYear:2025

-

View ProductWorking area:3000x1500 mmPower:1 Kw - 50 KwMaximum thickness:20 - 50 mm on FeAutomation:Sheet loading and unloadingYear:2025