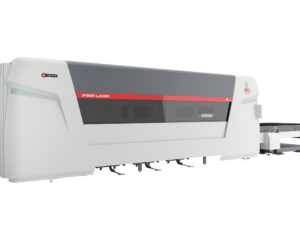

Laser Cutting Machine CutLite Penta model PLUS

- Manufacturer: CutLite Penta

- Working area: 15000 x 3000 mm

- Power: 2 Kw - 50 Kw

- Condition: New

- Maximum thickness: 10 – 50 mm on Fe

- Automation: Sheet loading and unloading

- Year: 2025

Power Source from 2 kW to 50 kW

Working area from 15000×3000 mm to 15000×3000 mm

The most high-performance machineThe PLUS family of laser systems from Cutlite Penta combines very high quality, high productivity, and low operating costs.

The quality of movement is guaranteed by the best linear motors available on the market which, together with the Fiber laser source, allow for high dimensional accuracy in cutting both carbon steel and stainless steel.

EVO 3 Head

The EVO3 cutting head is equipped with a capacitive sensor. The FIBER PLUS system uses the autofocus cutting head EVO 3 which, entirely designed by our research and development department and made with high-precision mechanics by Cutlite Penta, is also equipped with contact and temperature sensors.

The head itself and the focusing lenses can be used up to 50 kW of laser power and at a pressure of 25 bar; different focal configurations are provided.

Laser sources

Fiber laser sources allow great versatility and enable the cutting of multiple types of metals. Developed as a unique system, it can be paired with a wide choice of optical fiber diameters. High efficiency, excellent beam quality, and low electrical absorption are the distinctive features.

The source is housed in a conditioned and sealed NEMA 12 cabinet to operate even in hostile environments.

The high reliability of these sources ensures very low maintenance costs.

Mechanical structure

The base is a structure made of electro-welded steel, thermally stabilized, which is then machined to receive high-precision guides and linear motors.

The Gantry structure is composed of aluminum alloy castings to which the beam made of steel is anchored, lightweight and rigid so as to compensate for thermal expansions without deformation. This configuration allows for remarkable dynamic performance.

Electro-welded steel structure

High dynamic performance

Thermal expansions without deformation