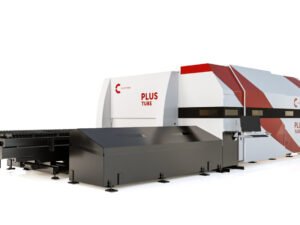

Cutlite Penta LME Tube

- Manufacturer: CutLite Penta

- Working area: 3000x1500 mm

- Power: 2 Kw - 15 Kw

- Condition: New

- Maximum thickness: 12 - 40 mm on Fe

- Automation: Sheet loading and unloading

- Year: 2025

- Controlled axes: Y1-2-X-R-Z1-Z2

Cutlite Penta LME Tube

The LME TUBE fiber laser cutting system represents the most flexible and multifunctional choice: the ideal solution for small/medium metalworking that combines compact size with excellent cutting quality and precision.

Choose the work area:

– 3000×1500 mm

– 4000×1500 mm

– 4000×2000 mm

– 6000×2000 mm

Choose the power from 2000W to 15000W

High performance for flat and tube processing

LME Tube combines the advantages of an LME system for flat sheet cutting with the new laser technology applied to tube cutting for the new FIBER Tube, making it a true tube processing machine.

The transition from flat to tube processing occurs automatically, and the cutting process uses the same EVO 3 cutting head, designed and developed internally by Cutlite Penta, and also includes the possibility of Bevel cutting on the tube. LME Tube represents the best value for money on the market and guarantees great flexibility of use with high cutting performance, maintaining a high-quality standard.

EVO 3 Head

The EVO3 cutting head is equipped with a capacitive sensor. The LME TUBE system uses the EVO 3 autofocus cutting head, entirely designed by our research and development department and manufactured with high-precision mechanics by Cutlite Penta, also equipped with contact and temperature sensors.

Bevel Head

The head designed by Cutlite Penta allows these operations to be performed without penalizing classic flat cutting. The head, innovative in its mechanics, has optimized dimensions, is lightweight and allows rotation of +/- 45° in both cutting directions.

Laser sources

Fiber laser sources allow great versatility and enable cutting multiple types of metals. Developed as a single system, it can be coupled with a wide choice of optical fiber diameters. High efficiency, excellent beam quality and low electrical absorption are the distinctive characteristics.

The source is contained in a conditioned and sealed NEMA 12 cabinet so it can operate even in hostile environments.

The high reliability of these sources guarantees very low maintenance costs.

Automatic loader

The LME TUBE system can be equipped with a tube loading and unloading system.

Maximum capacity 6 tubes with diameter ø 305 mm or maximum side 220 mm

Automatic tube loading from ø 20mm – max. ø 305 mm

Automatic loading lengths from 1500 mm to 6500 mm, expandable on request

Sliding surfaces entirely covered in plastic material to avoid damage and scratches on delicate tubes

Possibility of mounting on the operator side or rear area, to optimize the layout within the work area

Loading, unloading and storage

The PLUS TUBE system can be equipped with the sheet metal loading and unloading system in line or at 90° and with the addition of automatic storage warehouses.